Caldaia Controls Boiler Services

Boiler, Plant & Industrial Controls Services

Caldaia Controls provides a multi-discipline

approach to combustion tuning and analysis

Tuning industrial boilers for optimal efficiency.

Boiler tuning is an important maintenance item used to adjust the air to fuel ratio in the boiler and achieve maximum combustion efficiency – the measure of how effectively the heat content of a fuel is transferred into usable heat.

Beyond ensuring long term equipment life and operational reliability, highly efficient boiler systems can mean significant bottom-line cost reduction, NOx reduction and fuel savings. Boiler tuning should be performed each year to maintain peak efficiency.

A regular boiler tune-up provides an opportunity to verify current boiler operating performance and establish a baseline for optimization adjustments, such as fine-tuning the amount of excess air available to completely burn the fuel. Using the optimal amount of excess air minimizes heat loss up the stack and improves combustion efficiency. It is not uncommon for boilers to operate at greater than desired excess air levels, resulting in in heat lost due to the increased flue gas flow, which lowers the overall boiler fuel-to-steam efficiency.

NESHAP MACT & Government Compliance Testing Provided

All our testing equipment is maintained & factory certified according to national standards

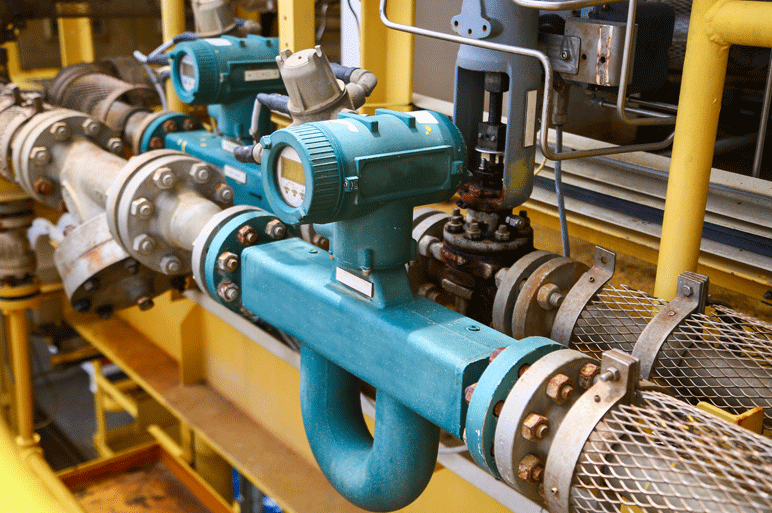

Industrial Plant Instrumentation & Control Systems

The right combination of process sensors, valves, control systems and programming is fundamental to the success of any industrial manufacturing process. The top target of every plant management or plant ownership is to achieve the safest and maximum production out of their equipment, machinery and devices. In order to reach that target, one of the major steps it follows is to install good instrumentation in the plant. We have the field-experience and technical know-how to support your next instrument and controls new installation, maintenance, update or upgrade project.